Applications and good monitoring practices articles

Compressor

Updated at 2/24/2023

Compressors are widely used in industrial processes to compress air and other types of gases. These machines have a wide range of applications in industries, going from compressed air supply for general applications to very specific ones, such as cooling of cold rooms in food processing industries. As equipment that generally work with high speeds and small clearances between its components, constant monitoring of this type of machine is recommended and can assist in anticipating potential faults.

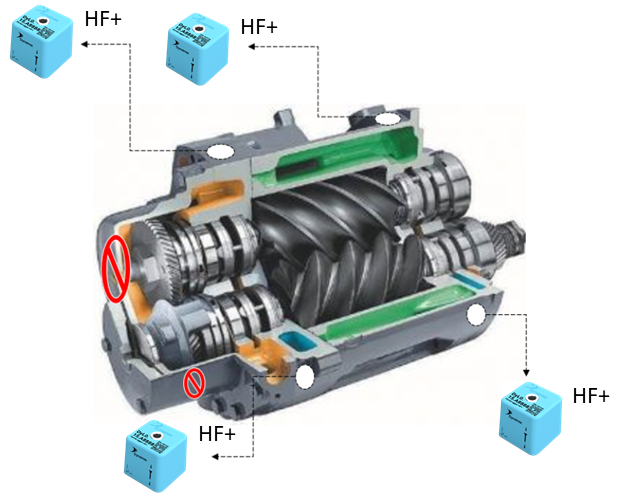

One of the predictive techniques that can be used for compressor monitoring is vibration analysis. Manufacturers commonly inform the monitoring spots on this type of machine. In general, the monitoring spots are indicated on the compressor input shaft (as close as possible to the gears and bearings), as shown in the figure below. DynaLoggers HF sensors are the most recommended for this task, since the compressors generally operate at high speed and their faults usually appear at higher frequencies. If vertical mounting is not possible, horizontal spots can be chosen.

Back to articles